Our Expandable Shafts

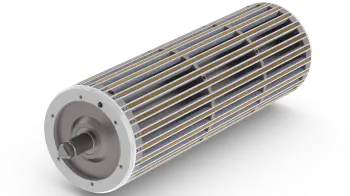

Type BEX

Multi-Bladder with Bars

A Lightweight and Powerful Shaft for Large-Diameter Mandrels

Designed for winding and unwinding reels of variable widths, these shafts are suitable for applications where the expanded length is crucial. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. In some cases, they can replace friction shafts. Lightweight and powerful, they offer an excellent compromise for achieving lightweight shafts with large mandrel diameters. They enable the transmission of significant torque. They are particularly suitable for use with cardboard, plastic, or steel mandrels. They are manufactured from aluminum or steel and can be equipped with aluminum or polyurethane bars. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of BEX-type expandable shafts allows the use of mandrels with diameters ranging from 200 to 500 mm.

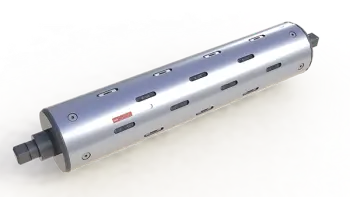

Type COE

Single Bladder with Shells

A Shaft for Sensitive Products (Winding with or without Mandrel)

Designed for winding and unwinding reels of variable widths, these shafts are particularly suitable for winding applications where the expanded length is an important factor. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. The "COE" model is recommended for winding/unwinding sensitive or fragile products that do not tolerate deformation of their mandrels. In the "COE P" clamping version, winding without a mandrel on materials with thicknesses ranging from a few tenths of a millimeter to several millimeters is possible. These shafts are made of steel, aluminum, or composite materials. Depending on the application, they are equipped with smooth, grooved, or vulcanized shells. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The possibility of "Large Expansion" shafts is also available. The range of COE-type expandable shafts allows the use of mandrels with diameters from 40 to 250 mm

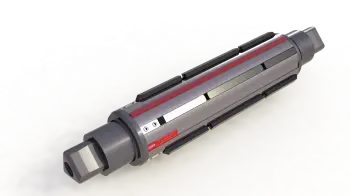

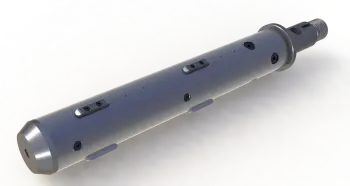

Type D

Single Bladder with Studs

A Robust and Versatile Solution to Your Winding/Unwinding Challenges

Designed for winding and unwinding reels of variable widths, these shafts are robust and powerful. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. They are suitable for use with cardboard, plastic, or steel mandrels. These shafts are made of steel, aluminum, or composite materials. Depending on the application, they are equipped with aluminum, steel, or polyurethane studs. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The possibility of "Large Expansion" shafts is also available. The range of D-type expandable shafts allows the use of mandrels with diameters from 25 to 500 mm.

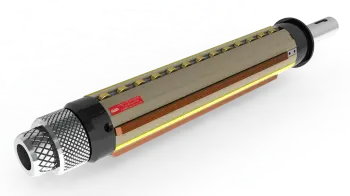

Type DCI

Single Bladder with Studs on Inner Shells

A Shaft with Reinforced Torque

Designed for winding and unwinding reels of variable widths, these shafts are robust and powerful. They can handle heavy loads and high web tensions. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. They are suitable for use with cardboard, plastic, or steel mandrels. These shafts are made of steel, aluminum, or composite materials. Depending on the application, they are equipped with aluminum, steel, or polyurethane studs. The internal thrust is maximized, allowing the transmission of significant torque. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The possibility of "Large Expansion" shafts is also available. The range of DCI-type expandable shafts allows the use of mandrels with diameters from 60 to 400 mm.

Type EXNG & EXLT

Multi-Bladder with Bars

A Lightweight and High-Performance Shaft

Designed for winding and unwinding reels of variable widths, these shafts are suitable for applications where the expanded length is crucial. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. They are manufactured based on extruded aluminum profiles. They are lightweight to handle and offer an excellent price-performance ratio. As standard, these shafts are anodized and equipped with pre-centering bars. Depending on the application, the bars are made of aluminum or polyurethane. This shaft model allows the bladders to be changed without disassembling the journals. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The possibility of "Large Expansion" shafts is also available. The range of EXNG & EXLT-type expandable shafts allows the use of mandrels with diameters ranging from 70 to 200 mm.

Type EXR

Pneumatic with Bars and Lateral Adjustment

A Shaft that Allows Reel Movement During Winding/Unwinding

Designed for winding and unwinding reels with low loads and in cantilever applications, these shafts allow the position of the reel to be adjusted relative to the machine frame without having to deflate the shaft. For fixed or rotating support axes, there are several solutions. The ECR or EXR versions allow the reel to be moved axially during film winding without the need to stop the machine. They are suitable for use with cardboard, plastic, or steel mandrels. Depending on the usage constraints, our shafts can be equipped with aluminum bars, smooth or grooved shells, and polyurethane for the EXR version only. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of EXR & ECR-type expandable shafts allows the use of mandrels with diameters ranging from 70 to 150 mm.

Type FRB

Pneumatic with Friction Rings

A Shaft Ensuring Winding Tensions for Multiple Reels

Designed for constant torque winding of multiple reels on the same shaft, despite variations in the thickness of the product being wound. Its design allows, on the same axis, the rotation at different speeds of all the reels. Possibility to work with very small reel widths (11 mm). It can be equipped with a rotary joint to allow constant tension winding. Its maintenance is facilitated by the use of standard and interchangeable drive rings. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of DCI-type expandable shafts allows the use of mandrels with diameters ranging from 40 to 250 mm.

Type MECA

Mechanical with Studs

A Shaft Dedicated to High-Speed Winding/Unwinding

Designed for high-speed winding and unwinding of reels, these shafts ensure excellent concentricity. They allow the use of one or several reels on the same shaft. Their range of use is very extensive. They have been developed for users who do not have or do not want to use compressed air. The expansion of the shaft is mechanical, which allows, depending on the operator's tightening, excellent torque transmission values. They can be made as half-shafts for cantilever applications. Simple and maintenance-free, this is a particularly robust shaft. Its airless design is useful for all work in vacuum chambers or applications with cycles lasting several days. This shaft model is widely used in the printing industry. These shafts are made of steel and are equipped with striated steel studs. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of MECA-type expandable shafts allows the use of mandrels with diameters of 70 and 76 mm.

Type MN

Single Bladder with Studs, Rotating Spindle Body / Journals

A Shaft with Rotating Spindle Body

They are suitable for use with cardboard, plastic, or steel mandrels. We manufacture our shafts in steel, aluminum, and composite materials. Depending on the application, they are equipped with aluminum, steel, or polyurethane studs. The custom manufacturing of our shafts ensures a perfect match between our product and your needs. Our technicians prioritize constraints such as torque, load, and speed to better meet your requirements. Our shafts are constructed based on studded shafts; they can be made with shells (MNCO) or with bars (MNEX). The manufacturing range of "Model MN" shafts allows the use of mandrels with diameters from 60 mm to 150 mm.

Type MPT

Mechanical-Pneumatic with Large Expansion

A Concentric Clamping Shaft for Large Diameters

The large expansion allows for great versatility in mandrel diameters. These shafts are suitable for high-torque and heavy-load applications. The change in mandrel diameter is very quick. The "mono-stable" pneumatic operation allows for easy installation in an automated machine. The steel jaws are suitable for use with cardboard, plastic, or steel mandrels. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of MPT-type expandable shafts allows the use of mandrels with diameters ranging from 275 to 305 mm.

Type SV & SVSA

Mechanical-Pneumatic

A Concentric Clamping Shaft for Small Mandrel Diameters

Designed for winding and unwinding reels of variable widths, these shafts are robust and powerful. They allow the use of one or several reels on the same shaft. They can be made as half-shafts for cantilever applications. They are specifically designed for vacuum applications. Their mechanical-pneumatic design ensures excellent concentricity values. The "SV" version expands by pressurizing the shaft (5/6 bar). The "SVSA" version expands when there is no air in the shaft. This is particularly useful for unwinding in vacuum chambers or applications with cycles lasting several days. The "SVSA" construction, meeting all safety requirements, can be used for handling and lifting reels. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of SV&SVSA-type expandable shafts allows the use of mandrels with diameters from 70 to 150 mm.