Expandable Ends

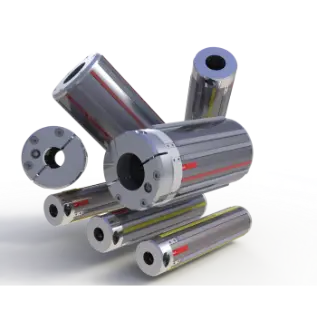

Type EC

Single Bladder Pneumatic End with Shells

A Versatile Pneumatic End

Designed to be used alone or in pairs on existing shafts, they are perfectly suited for the use of fragile mandrels. With quick attachment, they are particularly adapted for light applications, emergency repairs, and occasional use. The ends are made of steel for smaller models and aluminum for sizes with diameters greater than 100 mm. They can also be made in several shell lengths. The custom design and manufacturing of the ends ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of EC-type expandable ends allows the use of mandrels with diameters ranging from 70 to 200 mm.

Type MAP EXNG

Multi-Bladder Shaft with Bars and Through Bore

A Shaft that Fits on an Existing Bar

Designed to be used on existing bars, they are suitable for applications where the expanded length is crucial. They allow the use of one or several reels on the same shaft. They are manufactured based on extruded aluminum profiles. They are lightweight to handle and offer an excellent price-performance ratio. As standard, these shafts are anodized and equipped with pre-centering bars. Depending on the application, the bars are made of aluminum or polyurethane. This shaft model allows the bladders to be changed without disassembling the journals. The custom design and manufacturing of the shafts ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of MAP EXNG-type expandable shafts allows the use of mandrels with diameters ranging from 70 to 300 mm.

Type AS/EAS/MAS

Pneumatic Sleeve End

A Versatile Pneumatic End

Designed to be used alone or in pairs on existing shafts, they are perfectly suited for the use of fragile mandrels. With quick attachment, they are particularly adapted for light applications, emergency repairs, and occasional use. The EAS model is made of aluminum. The AS model is made of polypropylene, which reduces its weight and facilitates handling. The latest addition to the range, the MAS is a more compact aluminum model adapted for mandrels with a diameter of 150 mm. The custom design and manufacturing of the ends ensure perfect alignment with your needs, including your torque, load, and speed constraints. The range of AS/EAS/MAS-type expandable ends allows the use of mandrels with diameters ranging from 70 to 200 mm.